Top China Manufacturer of Double Column Vertical Lathes for Precision Machining

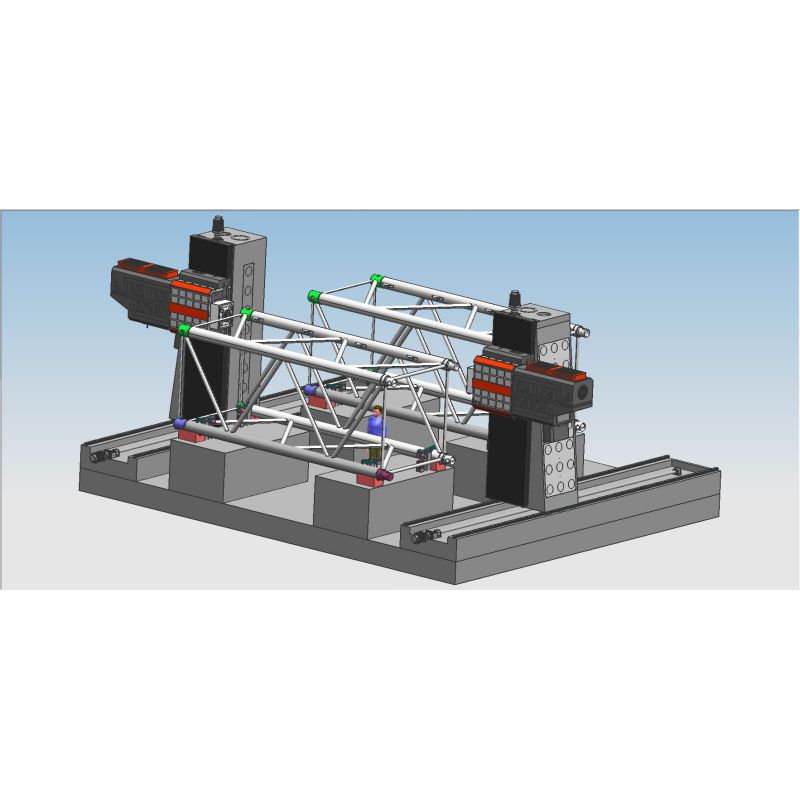

The Double Column Vertical Lathe is designed to meet the high demands of precision machining in various industries. As a leading manufacturer in China, we understand the importance of quality and efficiency for our B2B partners. This versatile lathe allows for enhanced stability and accuracy, making it perfect for large workpieces that require intricate detailing. Our Double Column Vertical Lathe features advanced technology, ensuring smooth operation and minimal downtime. Its robust construction and state-of-the-art design mean it can handle heavy workloads without compromising performance. We pride ourselves on delivering reliable equipment that enhances productivity and reduces costs. When you choose our lathe, you’re investing in a machine that is built to last, with parts that are easy to maintain. Let us support your business growth with our top-notch manufacturing capabilities and customer-focused service. Together, we can achieve the quality and efficiency you need to excel in your industry.

Double Column Vertical Lathe Market Leader Winning in 2025

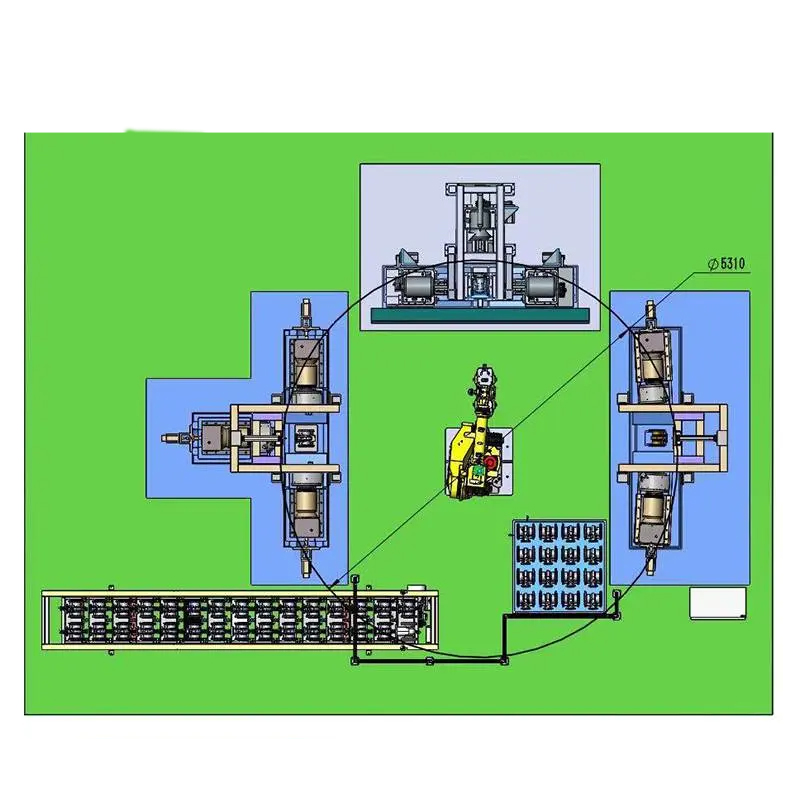

As industries evolve and technology advances, the demand for efficient and precise manufacturing processes has never been higher. The double column vertical lathe market stands at the forefront of this transformation, offering unparalleled advantages in versatility, size, and performance. By 2025, companies that leverage innovative solutions and cutting-edge technology will emerge as leaders in this competitive landscape. Those sourcing double column vertical lathes should prioritize suppliers who not only understand industry-specific needs but also provide tailored solutions that enhance productivity and efficiency. Global procurement trends indicate that buyers are increasingly looking for machinery that can adapt to a variety of applications and materials. Double column vertical lathes are designed to accommodate large workpieces while maintaining precision and stability. This adaptability makes them ideal for sectors such as aerospace, automotive, and heavy machinery manufacturing. Additionally, as sustainability becomes a central concern, state-of-the-art lathes equipped with energy-efficient technologies and lower material waste appeal to environmentally conscious buyers. In conclusion, as we approach 2025, the double column vertical lathe market will become increasingly competitive. Global buyers are encouraged to seek partnerships with manufacturers who prioritize innovation, customization, and sustainability. By focusing on these key areas, businesses can ensure they are equipped with the leading edge technology necessary to thrive in a rapidly changing industrial landscape.

Double Column Vertical Lathe Market Leader Winning in 2025

| Dimension | Market Share (%) | Growth Rate (%) | Key Strengths |

|---|---|---|---|

| Production Capacity | 25.4 | 8.5 | Technological Innovation |

| Customer Satisfaction | 30.1 | 7.2 | Strong After-Sales Support |

| R&D Investment | 18.7 | 9.0 | Cutting-edge Technology |

| Product Range | 22.3 | 6.7 | Diverse Offerings |

| Geographic Presence | 15.5 | 10.3 | Global Reach |

Related Products