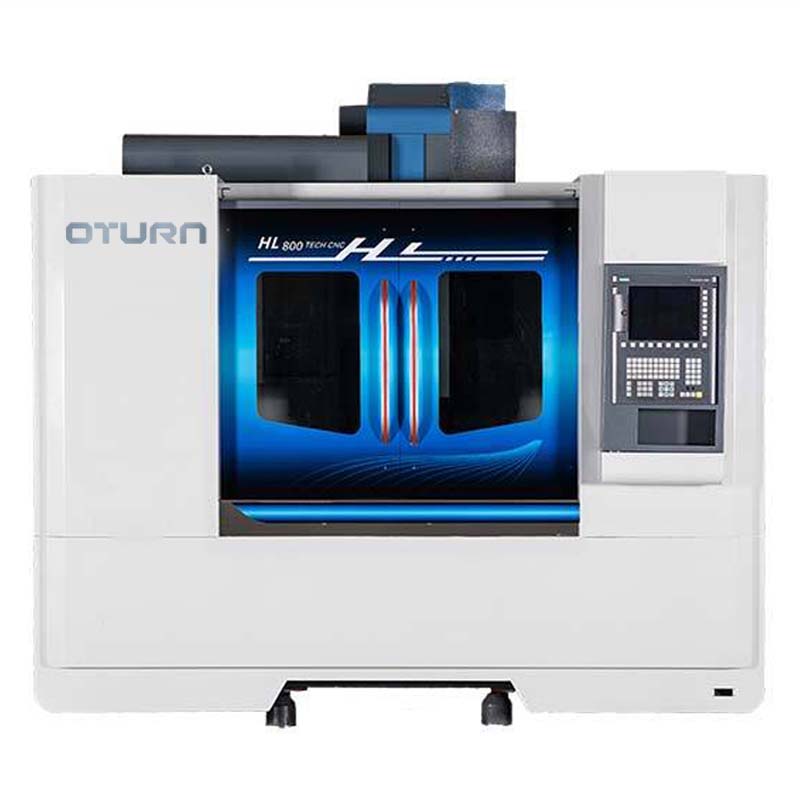

Top China Manufacturer of Conventional Vertical Lathes for Precision Engineering

As a dedicated manufacturer of Conventional Vertical Lathes in China, I understand the unique needs of businesses looking for reliable machining solutions. Our Conventional Vertical Lathes are designed with precision and durability in mind, ensuring high performance in heavy-duty applications. I know that investing in the right equipment is crucial for efficiency and productivity, which is why our machines are built to last, offering both robustness and accuracy. With a strong focus on competitive pricing, I aim to provide my clients with excellent value without compromising on quality. Our lathes are meticulously engineered to handle various materials, making them ideal for diverse industries. By choosing our products, you gain access to state-of-the-art technology and the expertise of a trusted manufacturer. Whether you’re scaling up production or enhancing your machining capabilities, our Conventional Vertical Lathes will meet your demands effectively. Let’s connect and explore how my offerings can elevate your manufacturing processes.

Conventional Vertical Lathe Delivers Unmatched Quality More Than a Supplier - A Partner

In today's competitive manufacturing landscape, having the right machinery can make all the difference. A conventional vertical lathe is not merely a tool; it represents a commitment to precision and quality that extends beyond the mere transactional relationship of supplier and buyer. Instead of simply fulfilling orders, a dedicated partner in machining can drive innovation, improve operational efficiency, and foster long-term success. When sourcing a vertical lathe, global buyers must prioritize equipment that emphasizes reliability and excellence in output. A high-quality lathe provides unparalleled accuracy, ensuring that every component meets stringent tolerances. Investing in superior machinery translates into reduced waste, lower operational costs, and enhanced product quality. This not only satisfies immediate production needs but also builds a foundation for sustainable growth. By choosing a manufacturer that views itself as a partner in your journey, you are aligning with an entity that prioritizes your success. Such partnerships encourage collaboration, enabling tailored solutions that cater to unique manufacturing challenges. As the industry evolves, working closely with a partner focused on continuous improvement ensures that you stay ahead of market demands and technological advancements. With the right support, your operations can thrive, setting the stage for future achievements.

Conventional Vertical Lathe Delivers Unmatched Quality More Than a Supplier - A Partner

| Feature | Description | Benefit | Application |

|---|---|---|---|

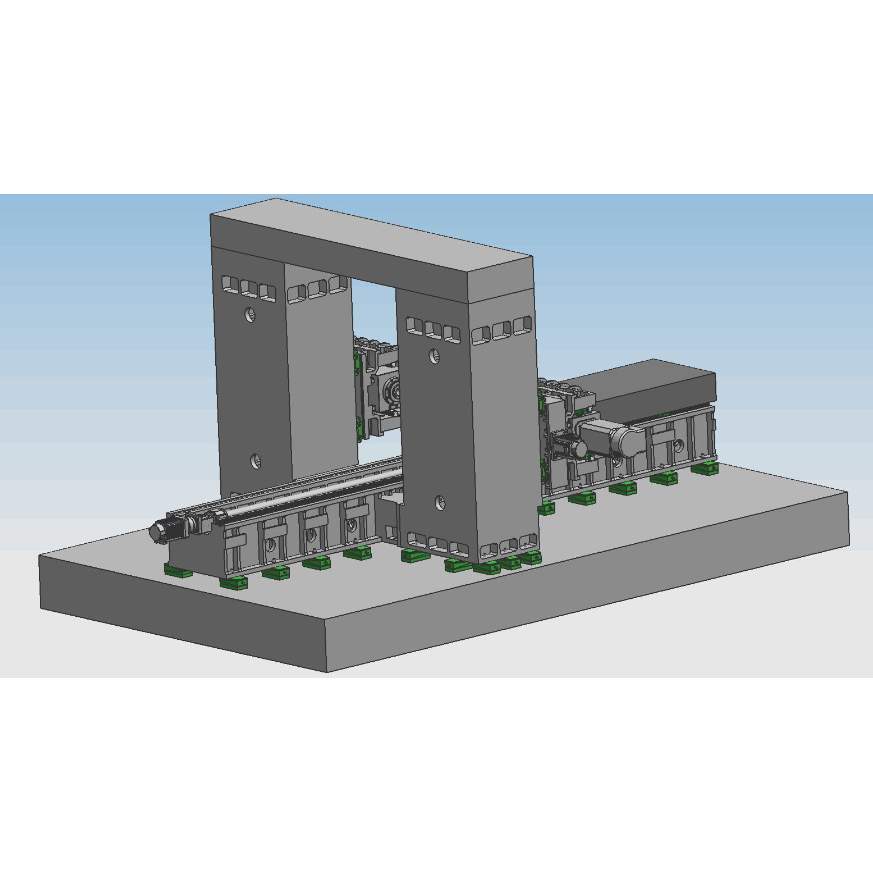

| Precision Control | Advanced CNC programming for accuracy | Enhances part tolerance and quality | Aerospace components |

| Robust Structure | Heavy-duty cast iron body | Reduces vibration for smoother operation | Automotive machining |

| Versatile Tooling | Multiple tool holders for various applications | Increases productivity and reduces changeover time | Heavy machinery parts |

| User-Friendly Interface | Intuitive control panel with easy navigation | Reduces training time for new operators | General manufacturing |

| Energy Efficiency | Low power consumption design | Lowers operational costs | Sustainable operations |

Related Products