Top CNC Vertical Machine Center Manufacturer in China for Precision Needs

When it comes to precision engineering, our CNC vertical machine centers stand out as a reliable choice for manufacturers in China. I’ve seen firsthand how these machines enhance productivity and efficiency in various industries. With robust construction and advanced technology, they deliver superior performance for complex machining tasks. Our CNC vertical machine centers are designed to handle diverse materials, ensuring that you can achieve the exact specifications required for your projects. Plus, their user-friendly interface makes operation smooth, even for those less experienced in CNC machining. By choosing our products, you’re investing in quality and durability that will serve your business for years. The versatility of these machines means they can be adapted for a wide range of applications, making them a smart addition to any manufacturing floor. If you're a buyer looking to elevate your production capabilities, our CNC vertical machine centers are exactly what you need.

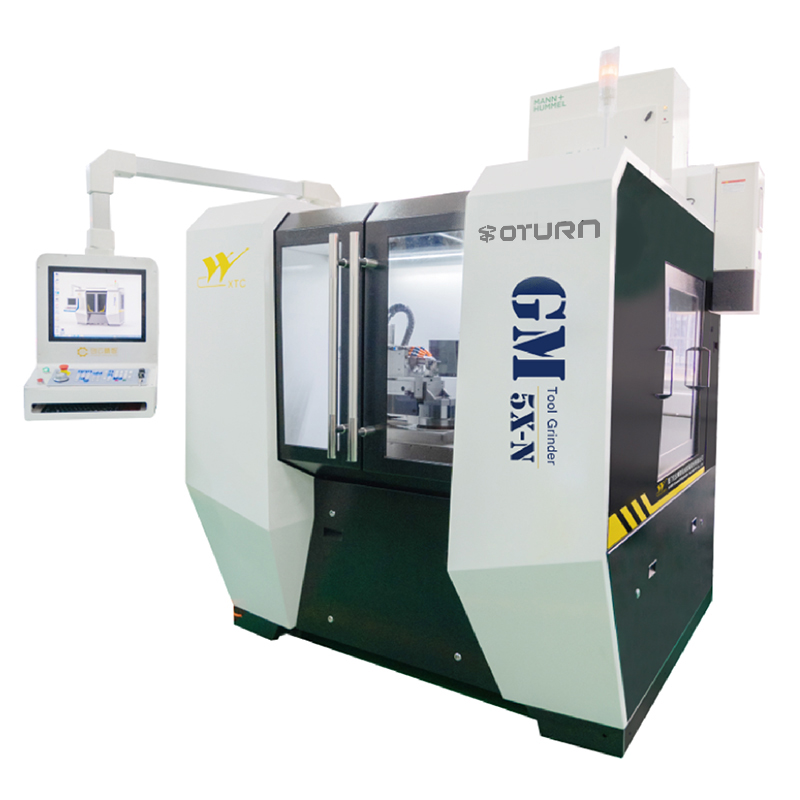

cnc vertical machine center Products Sets the Industry Standard

In today's fast-paced manufacturing landscape, the demand for precision and efficiency has never been higher. The advent of CNC vertical machine centers has revolutionized the industry, setting a new standard for quality and performance. These advanced machines offer unparalleled accuracy, allowing manufacturers to produce complex components with ease. By leveraging cutting-edge technology and innovative design, CNC vertical machine centers enhance productivity and streamline operations, making them essential tools for businesses aiming to stay competitive in a global market. Global buyers are increasingly recognizing the value of investing in CNC vertical machining solutions. These machines not only optimize workflow but also reduce waste and operational costs. Furthermore, their flexibility allows for quick adjustments to machining processes, accommodating a wide range of materials and designs. As industries shift towards more sustainable practices, the efficiency of CNC vertical machine centers contributes to a more responsible approach to production, appealing to environmentally-conscious companies. In seeking reliable partners for sourcing these machines, procurement professionals should prioritize suppliers that offer robust support and comprehensive technical expertise. Understanding the specific needs of diverse industries enables suppliers to provide tailored solutions that drive business success. By embracing the innovation and efficiency offered by CNC vertical machine centers, companies can ensure they remain at the forefront of technological advancement and meet the evolving demands of their customers.

CNC Vertical Machine Center Products Sets the Industry Standard

| Model | Axis Configuration | Max Workpiece Weight (kg) | Spindle Speed (RPM) | Tool Capacity | Precision (mm) |

|---|---|---|---|---|---|

| VCM-500 | 3-Axis | 500 | 12000 | 20 | 0.01 |

| VCM-800 | 3-Axis | 800 | 10000 | 24 | 0.01 |

| VCM-1000 | 4-Axis | 1000 | 8000 | 30 | 0.005 |

| VCM-1200 | 5-Axis | 1200 | 15000 | 40 | 0.002 |

Related Products