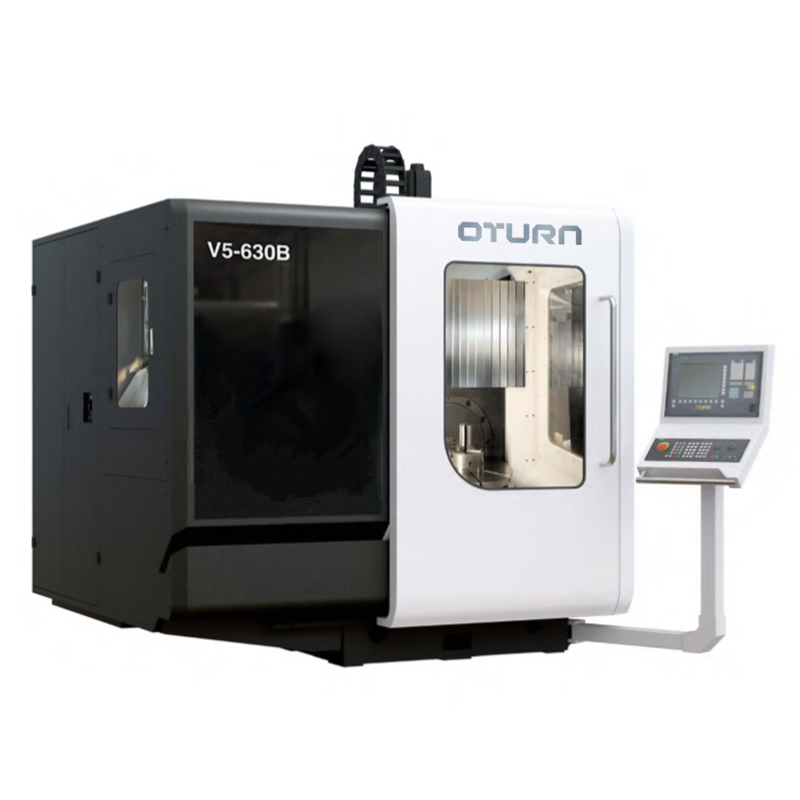

Cnc Vertical Lathe Manufacturer in China - Quality and Precision Solutions

When searching for a reliable CNC vertical lathe, I know how crucial it is to find a trusted manufacturer in China. Our CNC vertical lathes are designed to deliver precision and efficiency, catering to a wide range of industries. I’ve seen firsthand how these machines enhance production capabilities, making them ideal for both small workshops and large manufacturing facilities. What sets our CNC vertical lathes apart is their advanced technology and customization options. Whether you need to machine complex parts or simply enhance your workflow, our lathes bring value to your operations. Plus, being sourced from a well-established manufacturer in China means you are getting not just quality, but also cost-effectiveness. Investing in our CNC vertical lathe means investing in superior performance and durability. Let me help you take your production to the next level with machinery that truly works for you. Don’t miss out on the opportunity to elevate your business operations and efficiency today!

Cnc Vertical Lathe Application Factory

In the world of precision manufacturing, CNC vertical lathes have emerged as vital tools that enhance productivity and improve operational efficiency. These machines empower manufacturers to produce complex and high-quality components with unparalleled accuracy. The versatility of CNC vertical lathes makes them suitable for various applications across diverse industries, including automotive, aerospace, and metal fabrication. By utilizing advanced technology and automation, these machines significantly reduce cycle times while ensuring consistent quality in production. Moreover, the growing demand for customization and flexibility in manufacturing processes has further propelled the adoption of CNC vertical lathes. Their ability to handle a wide range of materials, from metals to plastics, positions them as a crucial asset for companies looking to adapt to market changes swiftly. Additionally, the integration of modern software solutions allows manufacturers to optimize machining processes, resulting in cost savings and enhanced production capabilities. As global buyers seek reliable suppliers, investing in high-quality CNC vertical lathes will undoubtedly provide a competitive edge in today’s fast-paced manufacturing landscape.

Cnc Vertical Lathe Application Factory

| Application | Material Type | Precision (mm) | Max Diameter (mm) | Max Height (mm) |

|---|---|---|---|---|

| Automotive Parts | Steel | 0.02 | 600 | 800 |

| Aerospace Components | Aluminum | 0.01 | 500 | 600 |

| Machinery Parts | Cast Iron | 0.03 | 800 | 700 |

| Electronics Housings | Plastic | 0.05 | 300 | 250 |

| Medical Devices | Titanium | 0.02 | 200 | 150 |

Related Products