CNC Hobbing Machine Price from Top Manufacturers in China

When it comes to CNC hobbing machine price, I know that quality and efficiency are top priorities for manufacturers in China. Our machines are built with precision in mind, designed to enhance productivity while ensuring the best possible output for your manufacturing needs. Being a dedicated manufacturer, I understand how crucial it is to balance affordability with cutting-edge technology. I really focus on offering machines that not only fit budget but also maintain high performance. Each CNC hobbing machine goes through rigorous testing to ensure reliability in demanding environments. If you're an industry player seeking to streamline operations and boost your production levels, I can help you find the right machine at a competitive price. Let's connect and discuss how our robust solutions can meet your requirements and support your business growth efficiently.

Cnc Hobbing Machine Price Application Market Leader

When considering CNC hobbing machines, understanding the price factors and market applications is essential for global buyers. The CNC hobbing machine market has witnessed significant advancements, driven by the increasing demand for precision in the manufacturing sector. As these machines are pivotal for gear production, their role cannot be overstated. Buyers must keep an eye on technological trends, as innovations can introduce efficiencies that significantly impact pricing and operational costs. Furthermore, the application of CNC hobbing machines spans various industries, including automotive, aerospace, and industrial machinery. This versatility makes them attractive to a wide range of purchasing entities. Buyers should evaluate the specific needs of their production lines, adapting their choices based on the complexities of the gears required for their operations. Price can vary based on power, capacity, and additional features, which is why conducting thorough market research and engaging with suppliers is crucial for making an informed investment. In the competitive landscape, potential buyers also need to consider after-sales support and the availability of spare parts, as these factors influence the total cost of ownership. Global procurement strategies can be optimized by establishing relationships with leading manufacturers, ensuring not only cost-effectiveness but also reliability and quality in production processes. By aligning their purchasing decisions with market leaders and staying informed on price trends, businesses can enhance their operational efficiency and maintain a competitive edge.

Cnc Hobbing Machine Price Application Market Leader

| Application | Market Share (%) | Growth Rate (%) | Region |

|---|---|---|---|

| Automotive | 30 | 5 | North America |

| Aerospace | 20 | 7 | Europe |

| Industrial Machinery | 25 | 6 | Asia Pacific |

| Construction | 15 | 4 | South America |

| Defense | 10 | 3 | Middle East |

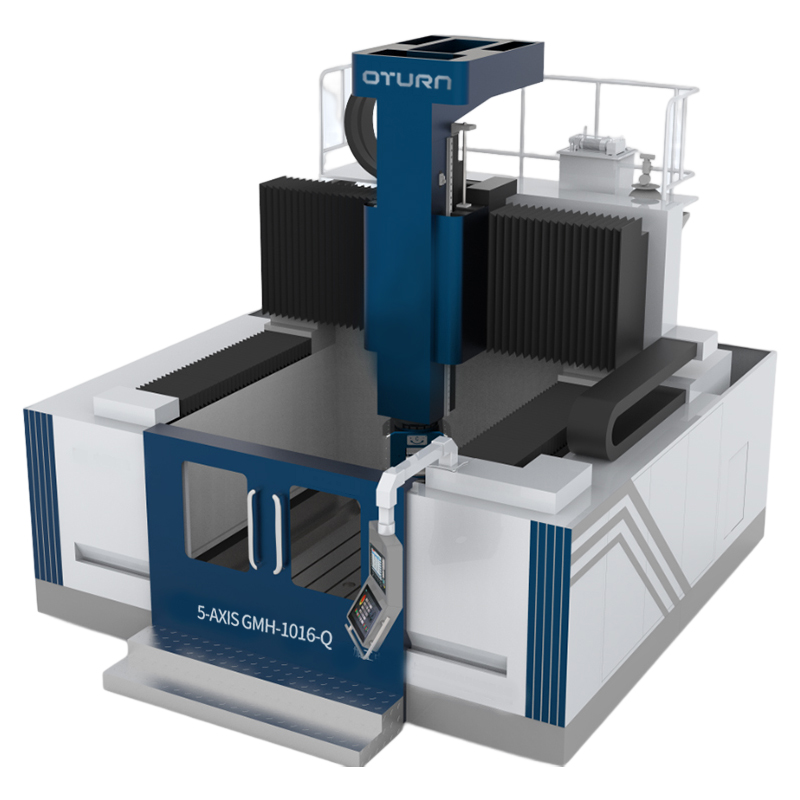

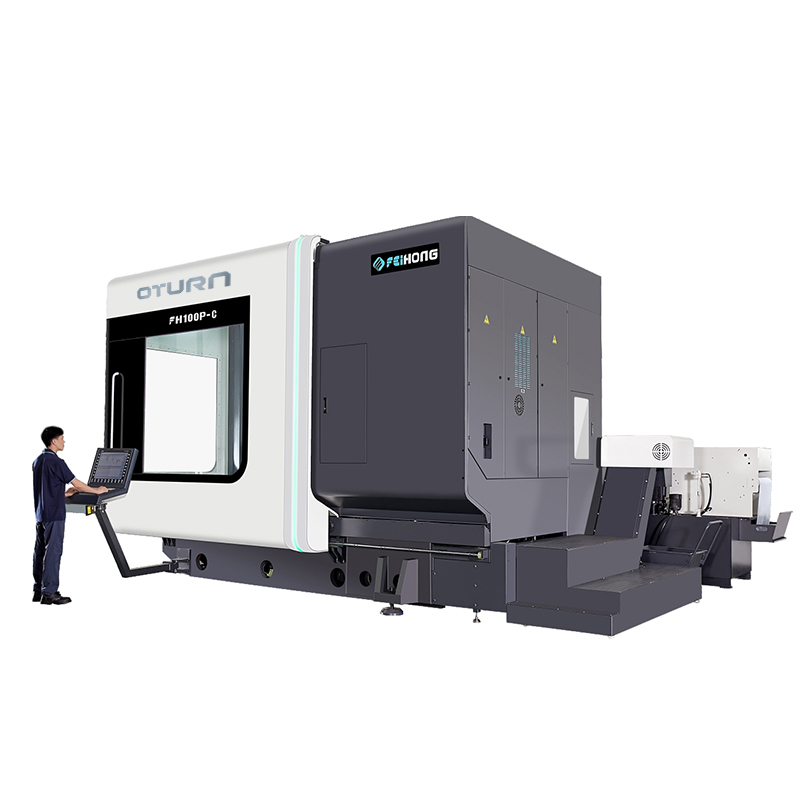

Related Products