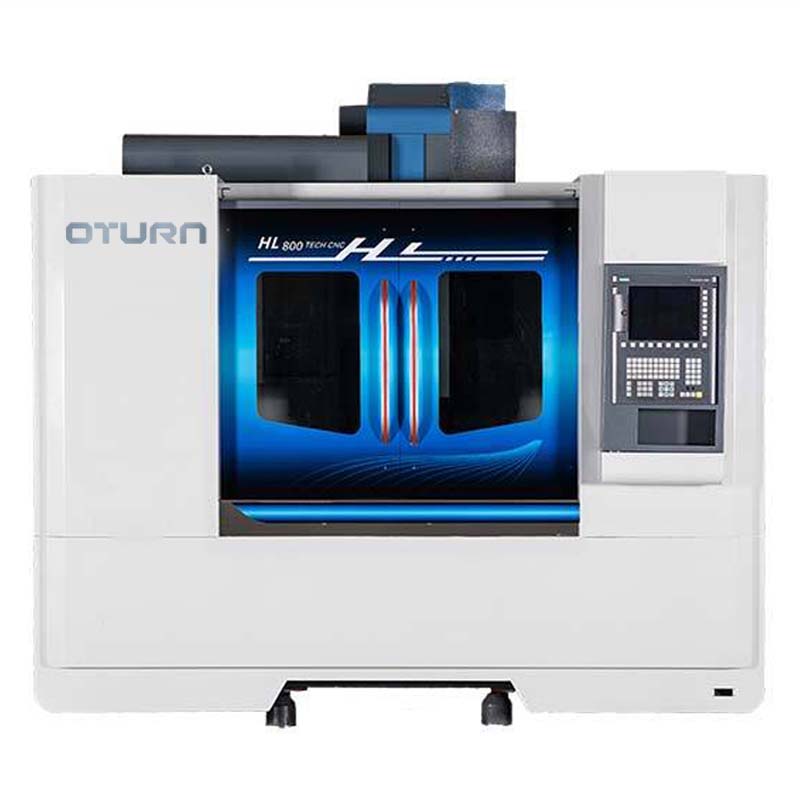

Top China Manufacturer of 5 Axis CNC Machining Centers for Precision

As a buyer seeking reliable solutions, I'm excited to share my experience with 5 Axis CNC Machining Centers made in China. These machines offer incredible precision and efficiency, making them perfect for complex machining tasks. When I started searching for a trusted manufacturer, I found that many Chinese manufacturers provide high-quality options at competitive prices. These machining centers allow for multi-dimensional processing, which means I can achieve intricate designs that would be impossible with traditional machines. Plus, the robust construction ensures durability and longevity, minimizing downtime in my operations. I've noticed that whether working with metals or plastics, the 5 Axis CNC machines deliver consistent results that enhance productivity. Choosing the right manufacturer is crucial, and I've found that these suppliers in China not only understand my needs, but also offer excellent customer support. If you're in the market for advanced machining capabilities, I highly recommend exploring these 5 Axis CNC options.

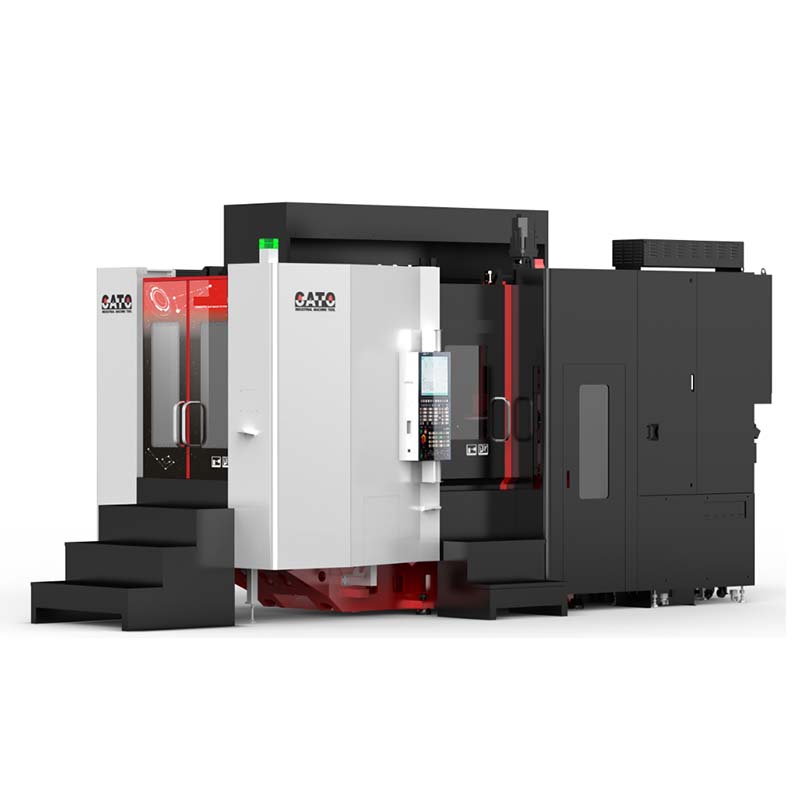

5 Axis Cnc Machining Center More Than a Supplier - A Partner Outperforms the Competition

In today’s fast-paced manufacturing landscape, the significance of a reliable partner in the supply chain cannot be overstated. A 5-axis CNC machining center is more than just a piece of equipment; it represents a pivotal investment in precision, efficiency, and innovation. When selecting a supplier, the discerning buyer should look for a partner that not only offers cutting-edge technology but also understands the unique requirements of their operations. This collaboration can lead to enhanced productivity, reduced lead times, and the ability to tackle complex projects that demand precision engineering. Choosing a partner with expertise in 5-axis CNC machining means gaining access to advanced capabilities that surpass mere transactional relationships. A true partner recognizes the critical nature of responsiveness and flexibility, adapting to fluctuating demands and customizing solutions to meet specific project specifications. This synergy can provide competitive advantages, such as improved product quality, reduced waste, and streamlined processes that ultimately lead to greater profitability and market success. Furthermore, a partnership grounded in mutual understanding fosters innovation and continuous improvement. Sharing insights into best practices, exploring new materials, and optimizing machining strategies can elevate a company's competitive edge. By selecting a partner that invests in ongoing development and technology advancements, global buyers can ensure that they are not just keeping pace with industry standards but are also positioned to set them. In a world where manufacturing excellence is key, collaborating with a true strategic partner is not merely an option; it is essential for long-term success.

5 Axis Cnc Machining Center More Than a Supplier - A Partner Outperforms the Competition

| Dimension | Value | Performance Metric | Notes |

|---|---|---|---|

| Axis Configuration | 5 Axis | Precision | High precision machining capabilities |

| Max Speed | 12000 RPM | Machining Speed | Faster cycle times for increased production |

| Cutting Tool Type | End Mill | Tool Versatility | Supports a wide range of materials |

| Work Area | 500 x 500 x 500 mm | Workspace Capacity | Accommodates various component sizes |

| Control System | CNC Control | Ease of Use | User-friendly interface for operators |

Related Products